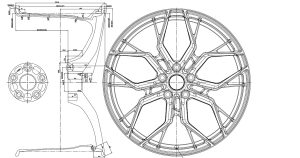

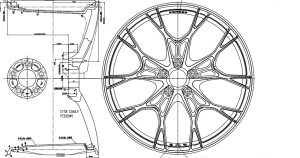

VR Forged wheels are not just made, they are born and cultivated into art before they meet their new owner. Starting out as a concept, wheels are designed in CAD analyzing each cut and corner to reach the ultimate goal. All wheels meet the VIA and JWL certification requirements that are extremely important over cost savings. Wheels are designed specifically for each vehicle and load rated to ensure the utmost in safety.

All wheels start out from the raw aluminum rod which is cut into the necessary sizing. Each aluminum rod goes through further analysis to sure it meets the standards set in place. From here, the aluminum rods go into a furnace to obtain the best forging temperature. The rods then go through the high tonnage hydraulic machines to complete the preliminary forging process. Utilizing a 10,000 Ton press, everything is inspected and verified to make sure the forged products are of extremely high quality.

The forging goes through the process to machine it into a more recognizable wheel shape. This is done by a three-rotary-wheel and 6-shaft LEIFELD machine. Each forging now goes through several heat treatments that enable the forged aluminum to obtain a more stable internal structure while improving mechanical strength and hardness.

The final forming of the aluminum wheels are in the CNC machine shop to turn them into the art forms as designed. Utilizing vertical double turret CNC lathes and a horizontal CNC lathe, the process of machining the forged blank into a wheel begins. Once the wheel completes its machining process, it then heads to a workshop that has special inspection checkpoint for each wheel. Verifying wheel run-out is just one of the analysis that happens to each wheel.

Next the wheels are ready to be coated to the desire color. Marked with detection codes, each product goes through flaw checking on a robotic cleaning line. This insures that the surface of each product is perfect and flawless. After several high pressure cleanings, the wheels are ready for coating and baking. After the custom color treatment, each wheel is then inspected further. There is a designated team responsible for dynamic balance inspection and size inspection to ensure the safety performance of the wheels.

Further random inspections are done with professional wheel testing equipment. These tests can consist of the dynamic corning fatigue tester, the bending endurance tester, 13 degree impact resistance tester, salt spray testing, and high end coordinate measuring machine are just some tests that are done as commitment to ensuring the best quality products available.

Once a wheel passes quality control, it is packaged meeting our requirements. As a large distributor of products that are shipped worldwide, we know the risks and damage that can happen during shipping. This is why all wheels are double boxed with extra rigid corners, rim protectors, and finally a neatly designed VR Forged wheel cover.